Electronic cams, PLC programming and servo drive design

IIn many industries, eg in packaging machines, servo drives are used because of their flexibility for generating motions with the "electronic cam" function. Often they replace mechanical cam gears. Even if our name with "NC-Kurventechnik" ("NC cam technology") indicates rather mechanical cams:

Since their introduction more than 25 years ago, we have optimized servo drive movements with electronic cams as well as mechanical cam gears.

Both are machine elements to control movements.

Our core business is the dynamically favorable design of movements ("motion design") to increase speed or processing quality in machines.

This works both with servo drives and with mechanical cams.

And that's just as important with servo drives as with mechanical cams!

High-quality motion design generally increases machine performance. Movement design is always a competitive advantage.

If you limit yourself to just jerk-free motion laws (5th degree polynomial and others) during PLC programming or electronic cams, you are giving away machine power.

At high speeds, a motion design is required that stimulates hardly any vibrations and keeps the accelerations, inertia forces and drive torques small. And all movements should be optimized in interaction, because of the numerous dependencies between them.

In this area our software OPTIMUS MOTUS is particularly strong. In addition to all the well-known laws of motion (5th order polynomial, Modified Sine, Inclined Sine, Modified Trapezoidal etc.), there are general sine combinations, higher polynomials with continuous third or fourth derivative, HS profiles, mHSL technology, numerically optimized polynomials, polynomial splines, polydyne functions and the inverse HS reaction to disposal.

OPTIMUS MOTUS is an extremely powerful cam editor.

Skip to ...

- Dynamic servo drive design

- Manufacturer-independent export of servo data

- Graphically interactive PLC programming of motion controls

- Software for PLC programming and electronic cams

- Calculation

To the homepage of Nolte NC-Kurventechnik GmbH

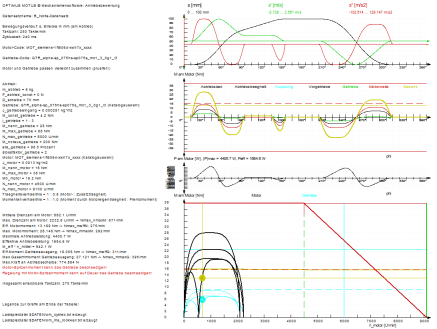

Dynamic servo drive design

OPTIMUS MOTUS software provides unique and powerful options for designing servo drive trains.

Particularly noteworthy are the very far-reaching motion design features, and that it deals with arbitrarily complex mechanisms with cams and linkages.

From an electronic catalog, the software automatically proposes the best possible combinations of servo motor and gearbox for a given movement task according to dynamic and constructional criteria.

OPTIMUS MOTUS considers ...

- the exact path-time profile at the motor shaft or the output for arbitrary motion diagrams

- distortions of the movements and the loads by any mechanism (slider-crank, four-bar linkage, six-bar linkage and all other coupling gears, cam gears, indexing gears, gear wheels, belts, etc.)

- freely definable load profiles in the mechanisms as well as masses, springs, gravity, friction

- the exact characteristics for the peak and rated drive loads

- rated and peak torque of motor and gear

- rated and peak speeds of motor and gear

- exact characteristics for the efficiency of the transmission

- whether motor and gear are structurally compatible at all

- the desired performance reserve for the drive train

When designing servo drives for packaging and other processing machines, OPTIMUS MOTUS goes much deeper into detail than industry-standard cam editors or sizers. Since the dynamic loads of the motor / gearbox combination fluctuate greatly even with small changes to the laws of motion and the transition times, and since linkages can completely change the load characteristics on the drive, the realistic design of the drive chain is only possible with such a detailed consideration of the motion and load connections.

OPTIMUS MOTUS servo drive dimensioning module was also one of the first dynamic motor and gear selection programs available on the market.

A special feature is that it is manufacturer-independent!

In packaging machines, bookbinding machines, assembly lines, filling machines and other processing machines, servo drives with electronic cams are used. Important design goals are

- high cycle speeds

- small, cost-effective drives

- flexibility

You need suitable drive components for the machine. The dynamic design of drive trains for electronic cams is by no means a trivial task due to the nonlinearities of kinematics. If the assumptions for the design are too simplistic, the design results may differ greatly from reality.

If drive components are dimensioned too small, you cannot achieve the required performance, and the machine delivery is delayed by weeks or months because of the delivery times of the components.

If the motor and gearbox are dimensioned too large, the construction is expensive and wastes energy.

Safety in the design of electronic cams is only achievable if all the following data are taken into account:

- the linkages which are driven by the servo motors, such as slider-cranks, four-bar linkage or other mechanisms

- the exact path-time curve at the motor shaft or at the mechanism output with realistic specifications for motion laws and transition times after rough collision optimization

- the exact load profiles in the mechanism as well as masses, springs, gravitaty, friction

- the characteristic curves for peak and continuous load of the motor

- mominal and peak torques of motor and gearbox

- rated and peak speeds of motor and gearbox

- during slow operation the transmission efficiency curves

To produce lifting or pivoting motions, the servo motor or gear often drives a slider-crank mechanism, a four-bar linkage, or other mechanism type. When the motion range of these mechanisms is utilized, these linkages translate highly non-linearly, that is, the ratio between drive and output speed varies greatly.

The rocker-crank mechanism shown in the animation transforms a uniform rotation of the crank (left, green) an oscillating output rocker motion (right, red). The characteristics of the drive motion profile looks completely different than that of the movement on the output link.

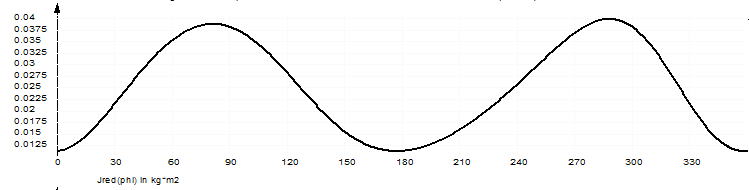

The reduced moment of inertia for such a mechanism with respect to the motor shaft is thus extremely variable.

You get completely wrong results if you calculate with constant moments of inertia in such cases.

For a correct drive design, the non-uniformity of the mechanism must be taken into account mathematically.

This is possible with the mechanism software OPTIMUS MOTUS .

Just as important as the mechanism kinematics is the definition of realistic, problem-related motion sequences for the drive design.

The rotational speeds on the drive depend linearly, the dynamic moments quadratically and the reactive power even cubically from the transition times of the individual movements. For example, there is a big difference in making a move in

a) 0.4 seconds or

b) 0.6 seconds

of transition time.

If a servomotor with a maximum speed of 6000 rpm was required for case a, then in case b one with 4000 rpm suffices.

If, for case a, a drive with 20 Nm peak torque is required, then in case b, a peak torque of 8.9 Nm is sufficient.

If 1200 watts of power are transferred in case a, in case b only 360 watts are used.

In addition, the characteristics of the various motion laws have an effect:

While in the 7th order polynomial there is a factor 7.51 for the dynamic drive torque, the Modified (Acceleration) Trapezoidal states only the factor 4.89. Depending on the application, other dynamic criteria of the laws of motion are also relevant.

Here is a particularly soft, anti-vibration movement design with continuous jerk function (yellow):

Overall, a useful dynamic drive design can only be done if the motion diagrams have been optimized for acceleration and designed to avoid collisions between the involved movements with minimal gaps.

OPTIMUS MOTUS provides a powerful graphical displacement plan editor (Motion Designer) that automatically proposes acceleration-optimized, harmonic motion diagrams to the user. The savvy user can refine these motion diagrams by adding properties.

Kinetostatic analysis

After calculating the motion sequences on the coupling mechanism in OPTIMUS MOTUS, masses, springs, process forces, process torques, gravity and joint friction are applied as loads. The resulting joint forces and torques are provided in diagrams, tables or animated vector plans.

These evaluations also enable the design of the mechanical drive elements in addition to the servo motor and the gearbox. Experienced users draw conclusions from the calculation results as to how the coupling mechanisms or the loads must be changed in order to obtain even more machine performance.

With the results from the calculation of torque and motion characteristics at the gear output, the motor / gearbox combinations are designed dynamically in OPTIMUS MOTUS. The user can save and track any number of design variants in parallel.

From an extensive catalog of several thousand motors and gearboxes, the user selects the suitable components for his motion task. The software supports him in many ways:

- The search in the catalog can be limited several times according to criteria such as rated torque, peak torque, rated speed, search strings or manufacturer.

- The user can extend the catalog with his own drive components.

- Users can put together the preferred motors and gears to a favorites list.

OPTIMUS MOTUS searches the complete catalog for the best motor / gearbox combinations within seconds.

Found motor / gearbox combinations are dynamically evaluated in a detailed graphic.

The evaluation takes into account, among other things, rated and peak torques of motor and gear, permissible speeds for motor and gear, dynamic characteristics for continuous and peak loads, characteristics of transmission efficiencies and controllability of the powertrain.

The graph clarifies the type of dynamic load on the powertrain and which components can be deliberately changed for even better results.

Conclusion

The automatic motor and gear selection of the OPTIMUS MOTUS software, combined with the illustrated design diagram, enables reliable dynamic drive design within a very short time.

OPTIMUS MOTUS is therefore the ideal tool for designing servo drive trains in high-speed machines, both for occasional users and for drive design professionals.

Manufacturer-independent export of servo data

We accompany servo drives with electronic cams since they were launched in the early 1990s. Since then we have been developing servo postprocessors for OPTIMUS MOTUS in order to export servo data as far as possible for all available controllers. Even today.

The library includes export in various neutral or common formats, eg

- csv

- csv with polynomial compression

- polynomials with coefficients or interpolation conditions

- as C source code

- as ST source code (eg for CoDeSys, SEW, Siemens, Allen Bradley)

- as source code in different macro languages

In addition, OPTIMUS MOTUS exports data in specific formats from the following manufacturers:

- Elau / Schneider (pp3 files, MAx4 files, ECAM-4)

- Allen Bradley / Rockwell

- Indramat / Bosch Rexroth

- Siemens

- SEW

- B+R (Acopos)

- Lenze

- Hauser / Parker Hannifin

- Stöber

- KEB

- Berger Lahr / Schneider

- Kuka

- Industrial Physics

- AMK

- ACD

- Bachmann

- APS Pickan

- ASB

- Wiedeg

- Mayr

- Keba

Our software OPTIMUS MOTUS even imports most of these formats.

Thus, OPTIMUS MOTUS becomes a vendor-independent converter for servo data: import the files of one manufacturer, then export them in another manufacturer's file format!

Interactive graphic PLC programming of motion controls

Movements can be described in the software OPTIMUS MOTUS not just for a single product format, but parametrically for a whole range of formats. There is a comfortable graphical editor available for this.

In kinematics and kinetostatic models, we simulate the effects of motion design on frame forces, drive torques and vibration excitation. Already with the movement design on the computer we can estimate the achievable machine performance and optimize the motion sequences forhigh dynamics.

The motion description is finally exported for the PLC world as source text in various language dialects:

- C

- Structured Text (ST) for CoDeSys

- Structured Text (ST) for Simotion

- Structured Text (ST) for Elau / Schneider Electric

- Structured Text (ST) for Allen Bradley / Rockwell

- Structured Text (ST) for SEW

From a user's point of view, this corresponds to a "save as" function.

Movements for specific product formats are finally calculated directly by the PLC control.

OPTIMUS MOTUS is thus a graphical editor for modeling, optimizing and testing complex motion sequences and finally exporting them as function blocks for the PLC world.

This allows PLC motion programs to be developed and modified much faster than manual program development.

The high motion quality known from cam technology also comes into play with servo drives and also increases the performance here.

Debugging is eliminated because the source code is generated automatically.

To the homepage of Nolte NC-Kurventechnik

Start Mechanisms Kinematics CamDesign Indexing MotionDesign Training Service CamCalculation Software Imprint PrivacyPolicy

11/06/21

• Software OPTIMUS MOTUS ® /

DasNolte ®

• All types of Cam Calculations

• Performance Optimizations

• Trainings and consulting

• App and Software Development

• PLC Motion Software

Cams, Mechanisms, Motion Design. Faster Machines. Since 1965.