Training and Education

The design of movements, cams, indexing cam gears and servo drive trains is crucial for machines' performance and durability.

Well-designed mechanisms with good motion design are no more expensive to manufacture than bad ones, but work much better and longer.

The core of our software and services business is making machines more powerful through good design of mechanisms and motions, faster, quieter and more durable. Over the decades, we gained a lot of practical experience, which we pass on today with workshops and trainings.

If you can only increase the speed of a machine earning your money by 5% by using a few of our tips, a workshop with us has usually been worthwhile. Often, however, we achieve a speed improvement by more than 40% when we optimize machines dynamically!

You benefit permanently from the ideas we share with you. Apply the knowledge to several machines and multiply your success!

All trainings are carried out online.

Appointments can be set freely.

For your special requirements, we also combine topics from various trainings into an individually designed training package.

Generally, we want to answer all your questions as part of our training and seminars.

We like to discuss all topics referring your specific tasks, as far as secrecy permits.

In all trainings, the main focus is on methods and improvements that can be integrated into your existing design practice without much effort and thus give you immediate benefits.

Skip to ...

- Cam design

- Motion design

- Energy efficiency

- Forces and torques in mechanisms

- Training OPTIMUS MOTUS

- Open Workshop OPTIMUS MOTUS

- Motion laws internally

- Linkage synthesis

To the homepage of Nolte NC-Kurventechnik GmbH

Cam Design

Take over the current state of the cam technology from the experts!

This seminar conveys the current know-how for designing cams. You question your existing cam designs and work out concrete improvements for the design of the motions and for the arrangement of the joints, levers, slides, etc.

Content:

- Design of cam disks, cylindrical/barrel cams, globoidal cams, general 3D cams

- VDI Guideline 2143, advanced motion laws, polynomial interpolation, polynomial splines, polynomial optimization

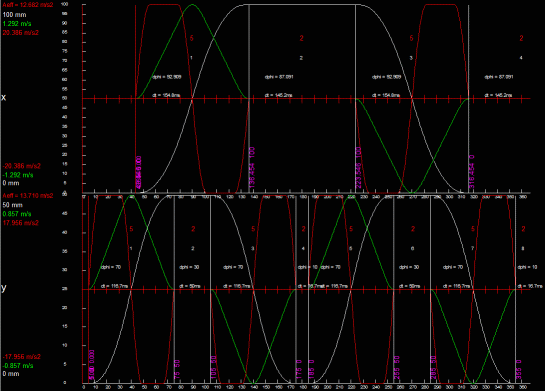

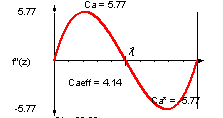

- Evaluation of motion diagrams: acceleration, jerk, ping, moment course, harmonic analysis

- Enforcement of the motion laws to achieve low accelerations, loads and vibrational excitations (motion design)

- Comparison of different motion laws

- Implementation of measured pathways, splines

- Evaluation of cam designs: transmission angle, radius of curvature, undercut, force on the roller, Hertzian pressure, drive torque, durability

- How to optimize the cam design

- Engineering and manufacturing aspects of cam design

- Active vibration and noise reduction: HS profiles, polydyne functions, mHSL

Motion Design

Use practice-proven and in-depth special methods of motion design to increase machine performance!

You will learn the current state of the techniques for designing highly dynamic motions. The seminar presents powerful methods in a practical way.

Content:

- Basic and common motion laws

- Advanced motion laws

- General polynomial interpolation

- Polynomial splines for smooth motions with continuous third, fourth, and possibly higher derivatives

- Polynomial optimization with tolerance tubes

- General sinusoidal combinations

- Cubic splines with and without smoothing

- HS profiles for vibration reduction

- Numerical HS optimization

- MHSL technology

- Polydyne functions and inverse HS reactions for resonance avoidance

- Motion design and evaluation: acceleration, jerk function, ping, moment course, harmonic analysis

- Enforce the motion laws to achieve low accelerations, loads and vibrational excitations, comparing different motion laws

Energy Efficiency

Learn how to make mechanisms and motions energy efficient in a simple way!

Machines should not only be fast, flexible, easy to handle and inexpensive, but also use as little energy as possible during operation. This seminar gives the participants tips and solution suggestions on how to optimize the energy turnover in mechanisms with cams, linkages and servo drives. For example, we show jerk-free motion laws that can deliver 22% less energy than the most favorable motion laws in the popular VDI Guideline 2143, and cams that theoretically shrink the drive torque and thus the power to zero. By clever arrangement of mechanisms and masses and springs, the power to be applied by the drive can usually be reduced to the compensation of the friction and the forming forces on the output, ie the unavoidable minimum.

Content:

- Calculating the drive torque from the power course

- Energy-saving motion beyond the VDI guideline 2143

- Design of power balancing mechanisms

- Power compensation cams

- Evaluation of dynamic designs with joint force and energy diagrams

- Eigenmotion

- Torque compensation with cams or linkages

- Torque compensation with non-circular wheels or indexing gears

- Dynamic design of as compact a servo drive train as possible, in a linear case with constant mass moment of inertia, in linkages with non-linear gear ratio and in smooth or unsteady drive of camshafts

- Overview of VDI Guideline 2149 on Mechanism Dynamics

Loads in Mechanisms

Optimize your machines energetically, powered by our experience! Increase speed and lifespan!

The computational investigation and optimization of the dynamic load in machines plays an increasing role in machine development, since machines are to run ever faster despite shorter development times. This seminar gives the participants a deep insight into the methods to determine the dynamic loads of cam and servo-controlled systems and to optimize the machines with simple means so that the loads and wear decrease and performance and processing quality increase.

Content:

- Overview of models for the dynamic investigation of mechanism loads

- VDI guideline 2149 volumes 1 + 2

- Reduced masses and springs, Jred(phi), flywheels

- Kinetostatic analysis, joint loads

- Toggle effect

- Evaluation of dynamic interpretations: game diagrams, joint force diagrams, polar diagrams, energy diagrams

- Calculating the drive torque over the power balance

- Total torques, natural motion, torque compensation with cams or coupling gears

- Brake and run-up simulation

- Mass balance

- Hertzian pressure in cam joints, lifetime estimation

- Dynamic design of servo drives even with non-linear translation

- Diagnosis of vibration phenomena

- Motion design considering vibration

- Active vibration prevention: HS profiles , HS optimization, polydyne functions

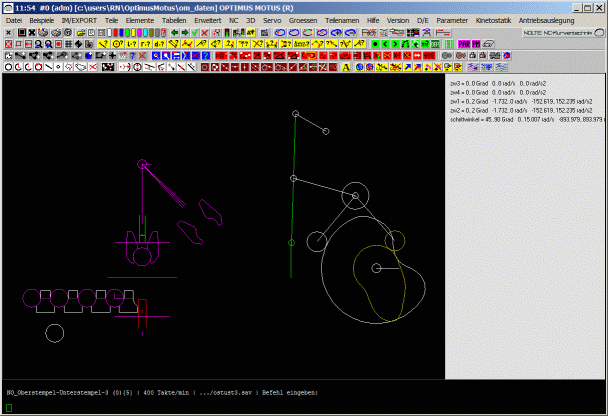

Training OPTIMUS MOTUS

Learn to optimize motions and mechanisms with OPTIMUS MOTUS software, or improve your skills!

Content:

- Geometry import and processing

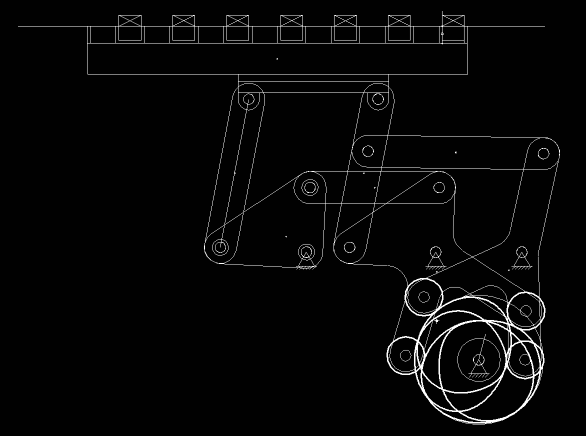

- Kinematics modeling, animation, collision optimization

- Graphical motion editor

- Motion design for fast and smooth machines

- Cam calculations (cam disks, cylindrical cams, NC and CAD data export, cam evaluation with diagrams and tables)

- 2D and 3D data export

- Mechanisms with multiple cams

- Table import, splines

- Cam analysis

- Calculation formulas, constraints, 3D coupling rods

- Gears, belts, chains, non-circular wheels

- Parametric simulation models, numerical dimension optimization

- Kinetostatics for evaluating drive torques, loads and lifetimes

- Servo drive design with motor and gearbox selection

- Export of PLC motion programs in ST

- 3D simulations

- Calculation documentation

Includes exercises

Also includes a 30-day practise license of OPTIMUS MOTUS (R)

Open Workshop OPTIMUS MOTUS

Training on the job! Kill two birds with one stone: learn software OPTIMUS MOTUS and at the same time solve calculation tasks in your daily business.

Content

In this open workshop, you will have the chance to individually review your specific questions about OPTIMUS MOTUS with us. Mainly you will work on you own mechanism examples and calculation tasks in dealing with the software OPTIMUS MOTUS. The care is as individual as possible and is adapted to your level of knowledge.

In preparation of the workshop you will get a 30-day license of OPTIMUS MOTUS for the workshop and subsequent exercises at home.

As part of the workshop, questions on all topics of mechanism technology can be discussed, for example:

- Motion design

- Cam evaluation

- NC data export and production

- Mechanism synthesis

- Servo drive design

Motion Laws

Duration: 1 day

Become an insider in motion design!

This seminar is about the theory behind the jerk-free motion laws that are used to create harmonic motions, that is, the current know-how of motion design.

Content: Formulas and derivations on the following topics:

- Motion laws from the VDI guideline 2143

- General polynomial interpolation

- Sinusoidal combinations

- Cubic splines

- HS profiles for vibration reduction

- Polydyne functions to avoid overshoots

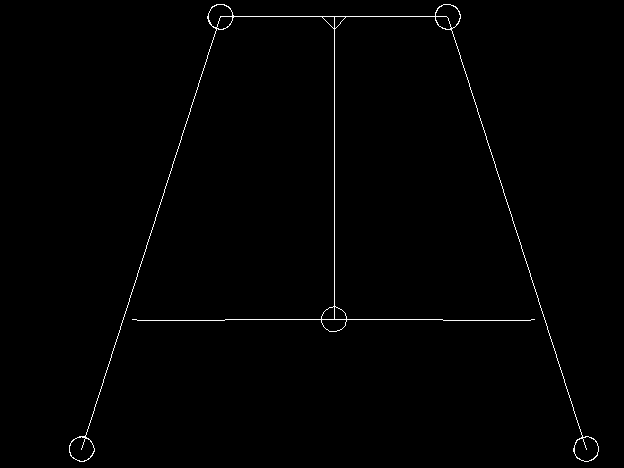

Linkage synthesis

Duration: 1 day

Good machines start with good kinematics!

Finding simple mechanisms to achieve a desired coupler curve or transfer function is still a major challenge for design engineers. Such mechanisms are still very common today, eg

- in hinges or fittings

- in steering rods of vehicles

- in high-speed processing machines

The seminar presents a general methodology on how to systematically find such coupling gears.

Content:

- Finding mechanisms from catalogs and solution collections

- Classical, graphic methods of gear synthesis

- Development of objective functions for numerical optimization

- Effect size calculation

- Search field calculations to find areas with attractive solutions

- Moving search field calculation

- Search step optimization for difficult target functions

- Composite optimizations

- Newton's method for finding exact solutions

- Example: linear guidance mechanisms

To the homepage of Nolte NC-Kurventechnik GmbH

Start Mechanisms Kinematics Software CamDesign IndexingCams Servo+PLC MotionDesign Training Service CamCalculation Imprint PrivacyPolicy

Cams Motions Energy Loads Training Workshop Parametrics Kinetostatics MotionLaws Synthesis

11/06/21

• Software OPTIMUS MOTUS ® /

DasNolte ®

• All types of Cam Calculations

• Performance Optimizations

• Trainings and consulting

• App and Software Development

• PLC Motion Software

Cams, Mechanisms, Motion Design. Faster Machines. Since 1965.